ITZEL INSPIRATION

SAND CORE

We ensure uniform wall thickness by the process of ‘core shooting’ on the brass ingots before casting. This ensures the uniform flow of water inside a faucet and the ultimate sensual feel of replenishing your skin with gentle swirls.

Quality Controls:

1) Sand and Catalyst composition

2) Core hardness

3) Core weight

INDUCTION CASTING OF BRASS

Made from brass ingots of high purity, density and superior grain structure, our products follow a

streamlined process in the induction casting of brass as per international standards.

Quality Controls:

1) Composition of Brass (CB7555-UNEN 1982- 2008)

2) Weight Standards

3) Uniform wall thickness (Internal / External)

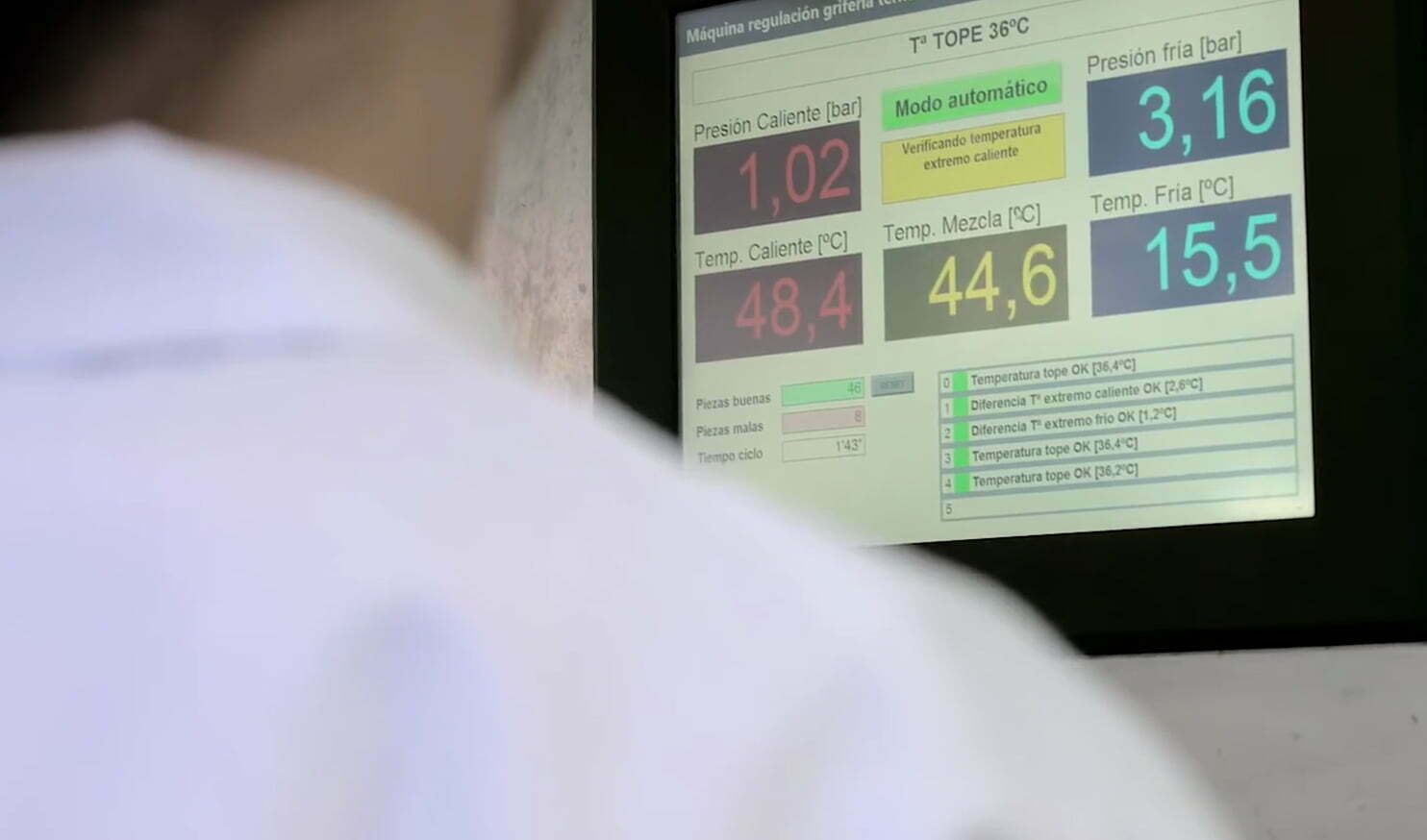

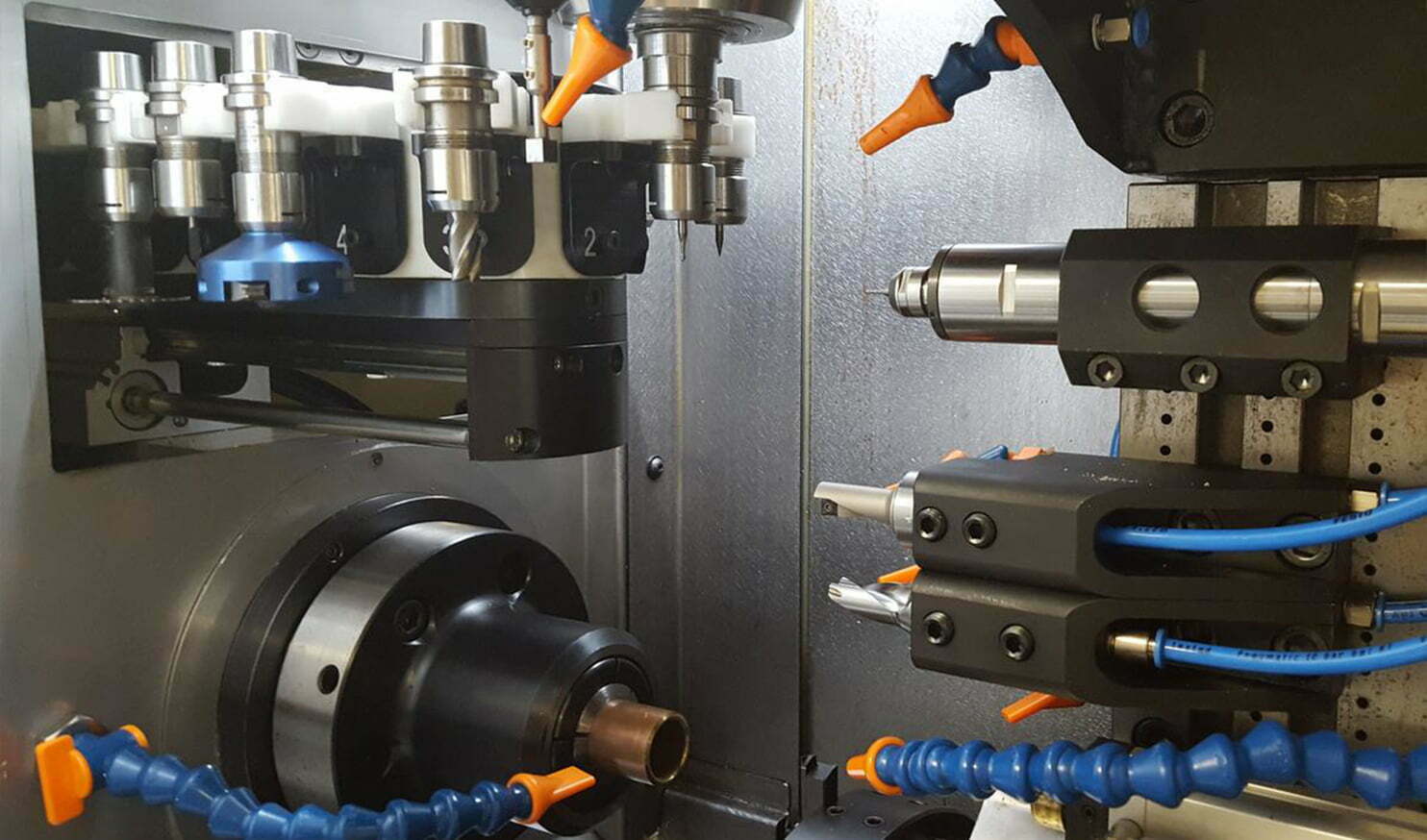

MACHINING

All our product components are processed on precision a machine which makes it standardized and easy to replace. The hardness and work ability make brass one of the most versatile machining materials available, making it possible to achieve an impeccable mirror-finish with sensual and exotic contours that add elegance and a tinge of luxury in every fragment of our design. The muted golden-yellow color of brass is refined to its finest by the use of imported brushing tools at our dedicated facility and ensures a long lasting life.

Quality Controls:

1) Dimensional controls drawings in technical documents respecting tolerance .

2) Thread Gauge (Go / No go).

3) Components fitment.

(ELECTROPLATING, POWER COATING AND PAINT)

(A) NICKEL PLATING: Latest ultrasonic cleaning system is used for cleaning and digressing the product before electroplating.

The thickness – nickle is minimum 10 to 12 microns as per international standards.

(B) CHROMIUM PLATING: Quality chromium plating system which is copper based is used for giving the best surface shine having very resistance against corrosion. Chrome thickness is minimum 0.3 microns.

Quality Controls:

1) Salt spray test to click durability

2) Adherence

3) Aesthetic Finish

4) Thickness of Nickel and Chrome

Preventative Maintenance & Services

Preventive Maintenance Services:

With ITZEL preventive maintenance services, routine care of faucets and showers are needed for smooth functioning of bathrooms:

- Regular Cleaning of aerators

- Regular cleaning of internal cartridges

- Regular cleaning of health faucets

- Regular Cleaning of blocked holes of showers and body jets

- Regular Cleaning of flush valve

- Regular managing flush valve flow.

- Chrome surface finishes with glitz- cleaning agent for water deposition on surface of bath fittings.

Quality Control

Quality is our passion

Our passion drives our business

Our main products include: Basin Faucets, Kitchen Faucets, Bath Faucets & Shower Faucets. We hold steadily to our mission statement to provide high quality cost effective products to meet our customers’ requirements in a timely manner.

Standards & Approvals: QSA International, UK EN 14516, CE certification, ISO 9001: 2008 International Quality System certification German.

Testing Details: Our quality assurance and control procedures are as follows:

- Material Inspection.

- Chemical laboratory examination.

- Composition testing and control system of original materials

- A testing and validation program whereby all our products are sampled and inspected.

We have established a procedure that checks products at all stages of manufacturing process:

Raw materials, in-process materials, validate or tested materials, finished goods etc. There is a regular and extensive inspection of assembly lines. All controls, Inspections, equipment, fixtures, total production resources and skills are inspected to ensure that they consistently achieve the required quality levels.

Quick Links

Collection

World of Itzel

Contact Info

Plot No.117, Sector 44, Gurgaon-122003, Haryana

+91-9137898989

info@itzelbath.it